关于三泰

About Santai

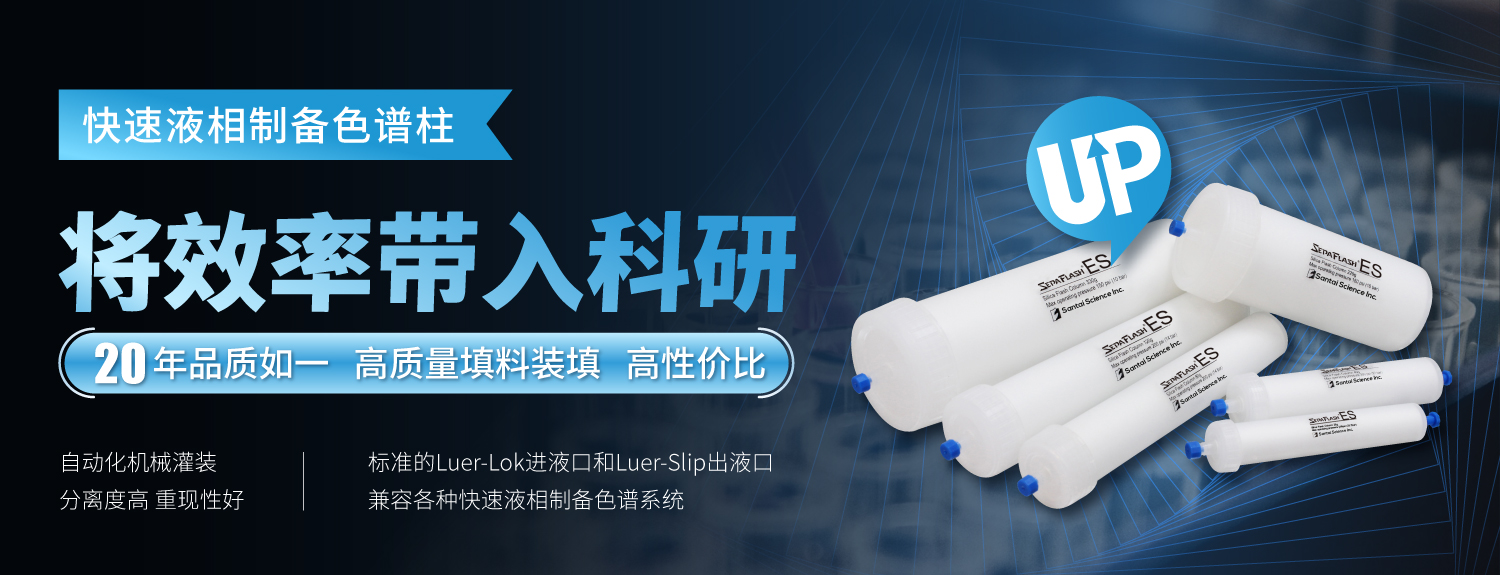

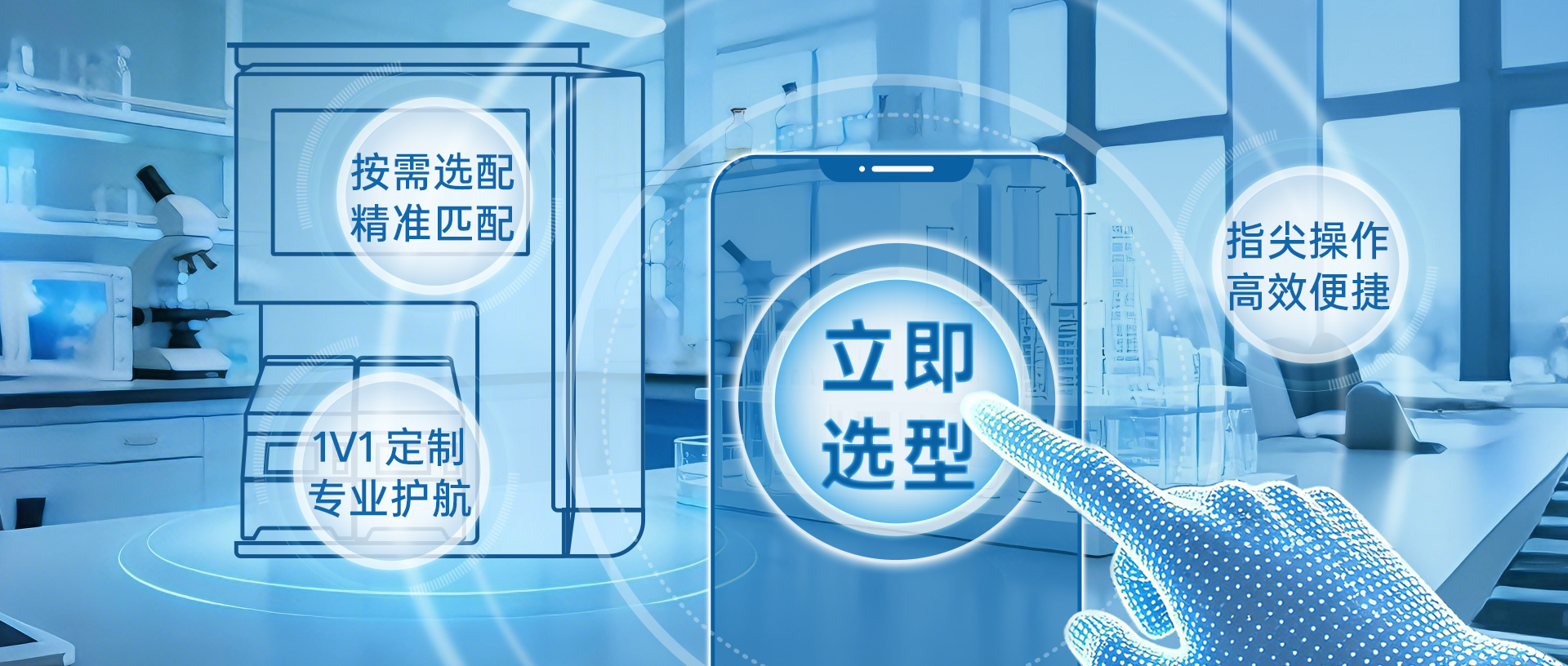

三泰科技成立于2004年,专注于分离纯化和合成技术的开发和应用,产品和服务主要应用于药物合成化学、天然产物、精细化工和石油产品等领域,主要产品包括SepaBeanmachine快速制备液相色谱系统和SepaFlash® 快速分离柱,ChemBeanGo®化学知识共享发布和科研用化学品的检索和交易平台,以及ChemBeanGo App等智能软硬件工具。

公司的应用技术研究中心还可以为客户提供分析测试及制备纯化服务。

公司的应用技术研究中心还可以为客户提供分析测试及制备纯化服务。

CN ▼

CN ▼ 400-662-9158

400-662-9158

常见问题

常见问题

操作手册

操作手册

维护保养

维护保养

在线报修

在线报修

在线购买

在线购买 ChemBeanGo®化学知识共享平台

ChemBeanGo®化学知识共享平台 CBG在线商店

CBG在线商店